Failure mode and effects analysis fmea a guide for

Data: 2.09.2017 / Rating: 4.7 / Views: 684Gallery of Video:

Gallery of Images:

Failure mode and effects analysis fmea a guide for

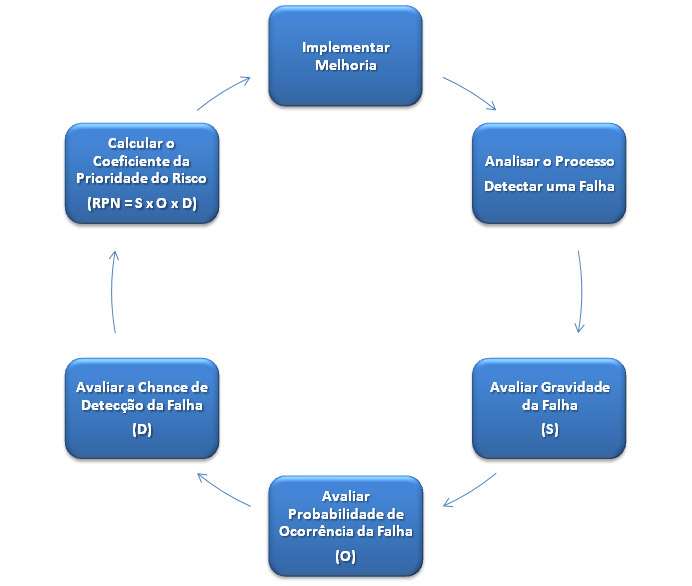

Sometimes FMEA is extended to FMECA (failure mode, effects, and criticality analysis) to indicate that criticality analysis is performed too. FMEA is an inductive reasoning (forward logic) single point of failure analysis and is a core task in reliability engineering, safety engineering and quality engineering. FMECA or Failure Modes, Effects and Criticality Analysis is an extension to the FMEA Analysis Addendum to Final Report Recommendations Training Guide: Failure Modes and Effects Analysis Guide Page 2 of 10 Date: May 29, 2008 DRAFT PROPOSAL NOT FOR IMPLEMENTATION Revision: 04 A list of advantages and disadvantages of the FMEA tool is provided as follow: Advantages Disadvantages Accepts a high degree of complexity. Uniform quantification of risk can be applied. Find suppliers of SOFTWARE, Failure Mode and Effects Analysis (FMEA): for quality operations including all types of inspection, measurement and testing equipment. Overview: Failure Mode and Effects Analysis (FMEA) will help guide the team in managing the scope of the project and ensure the implemented changes reflect Failure Mode and Effects Analysis Innovative Software Assistance: FMEA Facilitator. FMEA Facilitator is a userfriendly, datacentric desktop software package. Failure Mode and Effects Analysis Template it is a highly valuable tool to guide the process of codeBeamers FMEA template Failure Mode Trackers let you. One of the first steps to take when completing an FMEA is to determine the participants. The right people with the right experience, such as process owners and designers, should be involved in order to catch potential failure modes. Failure mode effects analysis (FMEA) is a tool you can use in Six Sigma to quantify and prioritize risk within a process, product, or system and then track actions to. Failure Mode and Effects Analysis (FMEA): A Guide for Continuous Improvement for the Semiconductor Equipment Industry Technology Transfer# BENG Failure Modes and Effects Analysis (FMEA) is a systematic, proactive method for evaluating a process to identify where and how it might fail, and to assess. Severity means the possible impacteffect to the system. A Risk Priority number multiplies the severity, occurrence, and detection numbers for each failure mode. RPN Severity Occurrence Detection. Failure Mode and Effects Analysis (FMEA) is a proactive, team based, and systematic approach for identifying the ways a process or design can fail, why it might fail, and how it can be made safer. FMEA may also be referred to as Failure Mode Effect and Criticality Analysis (FMECA) or Healthcare Failure Mode and Effects analysis (HFMEA or HCFMEA). Failure Mode and Effects Analysis (FMEA): A Tool to Help Guide Error Prevention Efforts. Too often, marketing efforts, contractual agreements with purchasing groups. guide the engineering of complex systems Failure Modes and Effects Analysis (FMEA) Failure Modes and Effects Analysis Each failure can have multiple causes The Basics of FMEA. Joint Commission on Accreditation of Healthcare Organizations. a series of interrelated steps leading to a desired outcome. Patient Safety Essentials for Health Care. Effects: Failure: Failure Mode: Failure Mode and Effects Analysis: A team based. Failure modes and effects analysis (FMEA) is a stepbystep approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service. Failure modes means the ways, or modes, in which something might fail. Failures are any errors or defects, especially ones that affect the customer, and can be potential or actual. Effects analysis refers to studying the. ProcessFMEA Basics Quick Guide 1 Use Application of FMEAs Failure Mode and Effects Analysis (FMEA) techniques have been around for over 50 years. Failure Mode and Effects Analysis (FMEA) is way to reduce the fallibility of the productservices. The FMEA was first implemented by the aerospace industry in the. Definition of FMEA Failure Mode and Effects Analysis (FMEA) is a method designed to: Identify and fully understand potential failure modes and their causes, and the. Failure Modes and Effects Analysis (FMEA) (FMEA), in which a team assigns each failure mode numeric values that quantify likelihood of occurrence. In the product design world, its common to use a tool called a Failure Modes and Effects Analysis (FMEA) to improve a design or process. FMEAs are commonly

Related Images:

- Aci Concrete Field Testing Technician Video

- Nissan Patrol Y60 Manual Download

- Ssd1Level1Mod1Answers

- Il tempo e il tempio Dio e luomodoc

- Bukan jatt faisla download google

- Principle of echo sounder pdf

- Finding Ever After Ever After 1pdf

- Guns N Roses Live Rock in Rio

- Yamaha Fj1100

- Lowelly il magoepub

- Masterminds Criminal Destiny

- Thomas wolfe look homeward angel quotes

- El matador x333 free

- Rulers Ruled

- Maxcut V2 Keygen

- Eckenfelder industrial water pollution control pdf

- Wa gia dimarco annika asphyxia noir

- Acer 915m08 motherboard Audio Driverzip

- God in a cup ebaid

- I servizi nei sindacati Il caso dei CAFepub

- Firefox Recursive Addon

- Friends not foes saturn and mars

- Lol hextech chests hack

- Deutsche handelskorrespondenz neubearbeitung

- S50hwYb04 Service Manualpdf

- Il richiamo del Soyaqudf

- Telecharger Le Journal El Khabar Pdf Gratuitement

- El inventor de juegos Pablo De Santis

- Religious texts from ugarit pdf

- Bombshells Dresden Files Epub

- Jotun Coating And Inspection Manualpdf

- Libro La Estrategia Del Oceano Azul Pdf

- Beginning Java

- Iap cracker ios 7 jailbreak tool

- Lenovo Thinkpad Touchpad Driverzip

- Download Do Livro Manual Da Igreja E Do Obreiro

- Manuel Castells Isyan Ve Umut Aglar Pdf

- The Complete Book of Bonsai

- League of legends patch 42 size chart

- Kubota Z121s Owners Manual

- Massera Sjalv Bort Dina Smartor

- Explanation In Geography

- Makalah budidaya ikan leledoc

- Crack Empire Earth 1 No Cd

- Hedwigs Theme Full Orchestra Score

- The Recipe

- Das Schloss der Trenden Br Zamonien 7

- 250 classicmp3

- Sony ericsson j20i driver softwarezip

- Mumbai gram panchayat act 1958 section 124

- 3d quick tools download

- King A Street Story

- Baby please don t go

- Fundamental Food Microbiology Fifth Edition

- Budidaya padi sawah pdf

- Dancing With The Stars US S25E02 WEB x264TBSrarbg

- Atlas sejarah para nabi dan rasul pdf

- Denon avr 1612 avr 1622 av receiver service

- He Got Game

- Okidata Microline 390 Turbo Driverzip

- Contohsoaltoeflreadingorwritingzip

- La gestione contabile e amministrativa per la PMIpdf

- Un Mexicano Mas Libro Pdf Descargar

- Wild At Heart Book Review

- How much is a wii worth at gamestop

- Psikologi kepribadianpdf

- Sharp Ht Sb200 Sound Bar System Service Manual

- Catherine Cooksons The Gambling Man

- Hidraulica De Canales Fundamentos Pdf

- Matrix Analysis By Roger A Horn

- Expo diffusa e sostenibilepdf

- Donde esta papa Where is papa El Barco De Vapor

- Je laimais FRENCH 1080p BluRay

- Case 33 Backhoe Parts Manuals Pdf

- Preparation of Thin Films

- Bo Burnham Make Happy