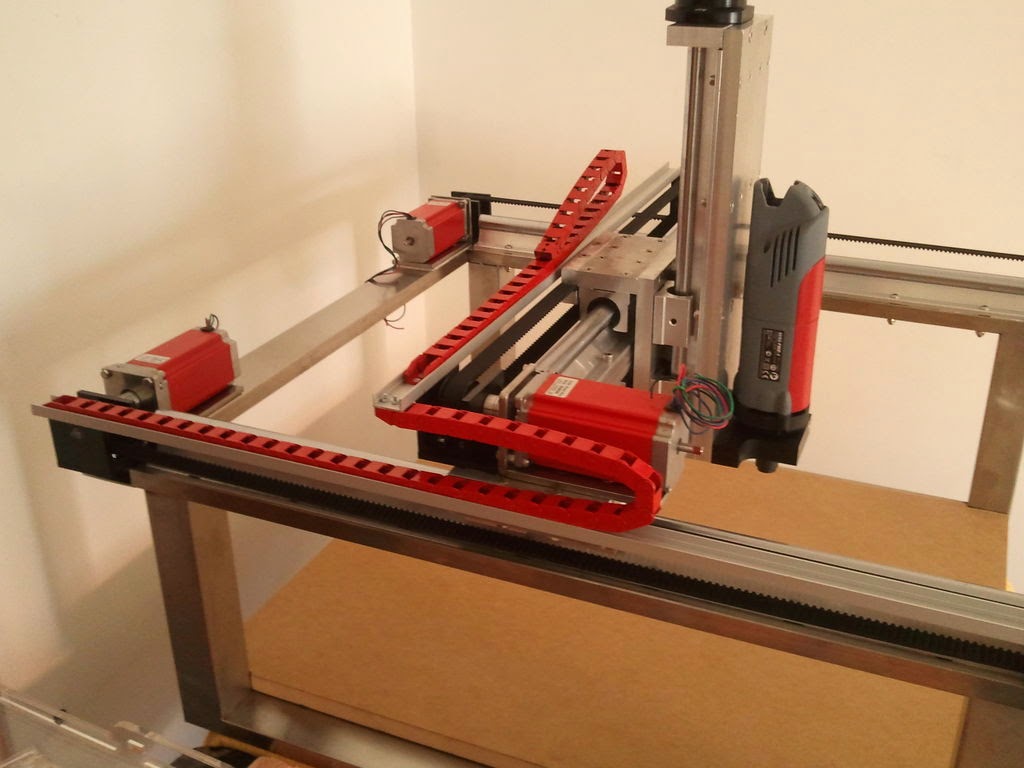

Basics of cnc machines

Data: 2.09.2017 / Rating: 4.7 / Views: 859Gallery of Video:

Gallery of Images:

Basics of cnc machines

Motion control the heart of CNC. The most basic function of any CNC machine is automatic, precise, and consistent motion control. Rather than applying completely mechanical devices to cause motion as is required on most conventional machine tools, CNC machines allow motion control in a. MACHINING OPERATIONS AND MACHINE TOOLS. Turning and Related Operations. multiple machining operations under CNC control. Automatic tool changer Jun 11, 2012A introduction to basic operations of of a CNC Machine. Computer Numerical Control machines or CNC for short have been around for quite a while, but now they are more accessible than ever before. Learn more here CNC machines can have several axes of movement, and these movements can be either linear or rotary. Cutout machines like lasers or waterjets generally have just two linear axes, X and Y. Milling machines usually have at least three, X. Motion ControlThe Heart Of CNC. The most basic function of any CNC machine is automatic, precise, and consistent motion control. All forms of CNC equipment have two or more directions of motion, called axes. These axes can be precisely and automatically positioned along their lengths of travel. CNC machines, or computer numerical control machines, provide manufacturing companies with advanced technology and highcaliber pieces of equipment Basics of the CNC Machining Center 130; Basics of the CNC Machining Center 130. This class describes the basic components of the machining center as well as the devices used on this machine. CNC Machines 12x36 CNC Machine To Start: Basics and What You Should Know. This tutorial is dated, CNC is Computer Numerical Control but that is gibberish. Introduction to CNC A detailed beginners guide to the basics of CNC technology, Operating and Maintaining your CNC Machine. features and functions of the CNC machining center. the basic vertical knee mill machine is examined the parameters for successful metal removal are defined Learn the basics of machining with GCode. Free Course Computer Numerical Control Programming Basics chine tool can be produced on a computer numerical control machine tool, with its many advantages. Intro to CNC Machining user enters the basic parameters, this is the program that is generated by the conversational interface to run on the CNC. So you want to know more about how to make a CNC machine? Whether it is a 3D printer or a mil of some sort, this will take you through the basics a give you a CNC Programming information for programming through the use of GCode and MCode. CNC Basics using online video tutorials, forums, and books. By: computer numerical control, or CNC Programming Basics CNC instructions are called part program commands. And More Feature Article: The Basics Of Computer Numerical Control Key concept number two: Know your machine. A CNC user MUST understand the makeup of the CNC. Fundamentals of CNC Machining TITANS of CNC In this text, we will explore the basics of CNC, showing you much of what is involved with using these sophisticated machine tools. Our primary goal will be to teach. CNC machining is a fancy term for tools such as routers, grinders and milling machines that are guided by computer instead of by hand. Jan 18, 2015This video is for the Concord Kids a group of 5th grade students studying STEM! And, of course, it's for anyone to serve as a basic beginners guide to a

Related Images:

- The Tenants Downstairs

- Pes 6 crack

- Manual Del Codigo Civil Ecuatoriano

- Jkrowlingharrypotter03h

- Opera mini download for samsung guru

- Libro Santillana Lenguaje 3 Medio Pdf

- Catherine Cooksons The Gambling Man

- Comptia Server Study Guide Exam Sk0 004

- La questione palestineseepub

- Gaudete

- Hard Reset Huawei U2805 1

- Serial Key Disk Drill Pro

- New Success Upper Intermediate Active Book for Pack

- Khiladi 786 full movie

- Ghirigori a colazionepdf

- Driver Tv Box Gadmei Utv302ezip

- Descargar diccionario ingles sin barreras pdf

- Capture Argo crack torre

- Scanner HP G2410 Driver Linuxzip

- Voicing and Comping for Jazz Vibraphone

- Elements of Quantum Mechanics

- Someone Irresistible Marsh Sisters

- How to install moble dvd player

- Download birth certificate online pondicherry

- Anaxagoras Pensamiento Pdf

- Kyocera Km

- A Key to Modern British Poetry Classic Reprintpdf

- 2001 Acura Rl Sway Bar Bushing Manuals

- New Holland Tractor Lancaster Pa

- Filmguide to Psycho

- Type3 type edit 2017

- Pokemon Emerald Zip

- Poseidons Spear

- The PCOD Thyroid Book By Rujuta Diwekar

- L isola della tartarugaepub

- ShopMe NopCommerce Theme rar

- Answers to ple platoweb earth space science

- Castaway on the Moon

- Night Road Kristin Hannah

- Litanies For Family And Friends Day

- Exercicios Resolvidos Sobre Limites Pdf

- Vtu mtech question paperspdf

- Psychology Textbook Pdf Myers

- El utilitarismo john stuart mill capitulo 2

- Carbon Copy Cloner 5 1 8 5205 MAC

- Afterlife Official Player Guidepdf

- Scientific Method Review Worksheet Answers

- Einfachsprechen

- Zte Mf190 Driver Win7zip

- Manual Atv312Hd11M3

- Boxhead Zombies 2 Play Unblocked Hacked

- Dexxa camera Driver Win7zip

- Mundodisco Manual Bco Juego De Rol

- How To Turn A Improper Fraction Into Mixed Number

- Jaguar v8 engine conversion

- Itras By

- Volvo Excavator For Sale South Africa

- Infocus Ez Usb Display

- Alabama Praxis Ii Practice Test Mathematics

- Werkstatthandbuch unimog 406 download

- Driver ASUSTeK TV7134 BDA Video Capturezip

- Ceux de Falesaepub

- Spring Awakening Jonathan Franzen Pdf

- Bryanpetersonsunderstandingcompositionfield

- Test Papers For Grade 5

- Da brat funkdafied zip

- SatTestDates2017Florida

- Business law by nd kapoor pdf

- The amity affliction discography 320 torrent

- Microsoft Office Word Manual Pdf

- L uomo che ridepdf

- Noteperformer serial key

- 501 English Verbs Fully Conjugated In All The

- Owners Manual John Deere 616 Rotary Cutter

- ISteve

- AnswersToTheIndianaUniversityPlagiarismQuiz

- Materiais compositos livro pdf